Subsequently, the aseptic filling approach begins, in which a filling mandril with precise needles injects the pharmaceutical liquid into your containers underneath sterile disorders, keeping container integrity.

If these solutions usually are not processed aseptically, it could stimulate contamination. Unfortunately, considering the fact that They can be immediately injected into delicate membranes, contaminated products can severely have an impact on the end person.

The enhanced production velocity specifically interprets to enhanced offer chain effectiveness. With more quickly production cycles, pharmaceutical companies can react promptly to industry requires and introduce new goods more rapidly.

All aseptic manufacturing procedures are done inside a cleanroom that must fulfill a variety of regulatory specifications to make sure the sterility and quality of drug products and solutions. Generally, a clear space is usually divided into two parts: the significant location and supporting thoroughly clean areas.

This website page doesn't exist in your selected language. Your desire was saved and you may be notified when a site may be considered in your language.

Additionally, the reduction in tools and space needs inherently lowers upfront capital expenditure. This end result of things helps make BFS a compelling here choice for pharmaceutical providers prioritizing effectiveness and financial freedom within their operations.

Put in on an variety of tube supplies, Quickseal® delivers dependable and immediate aseptic tube disconnection.

Assure that password amount security is in place and complies Together with the concepts of data integrity.

The Table underneath lists the main system parameters and their possibility to package deal integrity. These parameters have an effect on the packaging process.

Violation of business procedure and GMP guidelines. Disturbances in the cleanroom classification could lead to product contamination.

From your ingenious dip tube idea for maximum fluid elimination for the QUICKSEAL® aseptic disconnection, Mycap® can be an adaptable Option for virtually any software.

Microbiological advancement medium is utilized instead of the drug Answer for the duration of media fills to check whether or not the aseptic strategies are adequate to prevent contamination during actual drug production.

Aseptic fill end is required for the reason that numerous drug products can't be sterilized after filling as a consequence of sensitivity to heat, radiation and also other terminal sterilization methods which may impression product performance.

Though here we only use edited and approved material for Azthena solutions, it might on situations present incorrect responses. Be sure to ensure any data offered Along with the linked suppliers or authors. We don't deliver medical guidance, for those who look for clinical data you need to generally talk to a medical professional right before performing on any details supplied.

Scott Baio Then & Now!

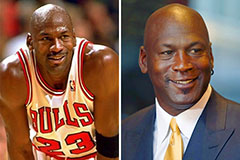

Scott Baio Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Michael C. Maronna Then & Now!

Michael C. Maronna Then & Now! McKayla Maroney Then & Now!

McKayla Maroney Then & Now! Stephen Hawking Then & Now!

Stephen Hawking Then & Now!